ASME EFx Drone Competition

ASME EFX Drone Competition

This project is my favorite to date. It captures everything I love about engineering and what drives me to keep learning.

Project Overview:

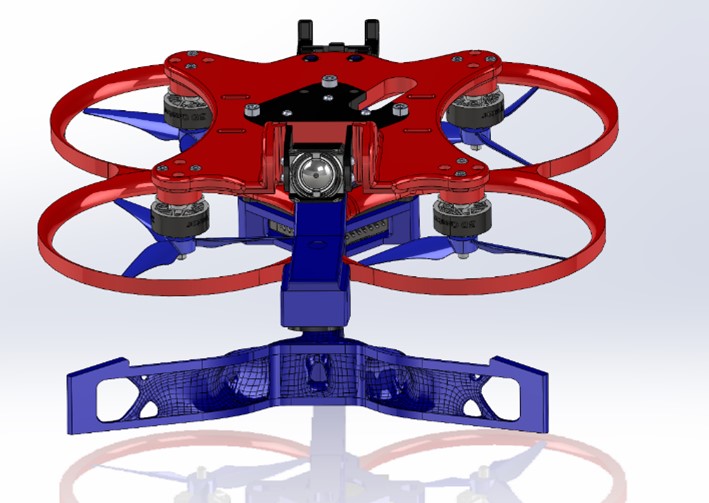

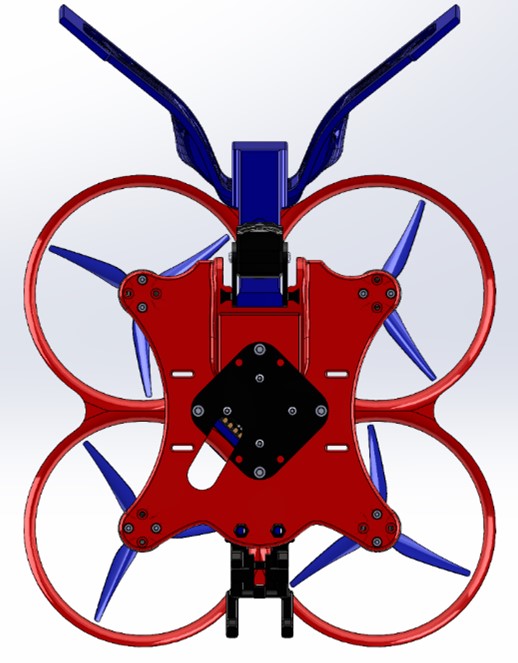

• Innovative Drone Design: Designed and 3D printed a custom First-Person View (FPV) drone for the national ASME EFX cargo drone racing competition, utilizing an iterative design process for optimal performance in payload pick-up and racing

• Senior Capstone Project: Developed this drone as part of my senior capstone design project, setting a precedent as the first team from UMass Lowell to enter the national ASME EFX cargo drone racing competition

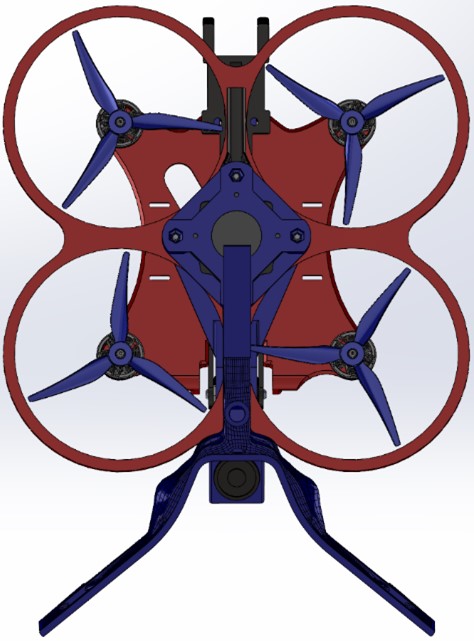

• Competition Success: Our team placed second at the national ASME EFX drone racing competition held at Virginia Tech, standing out with the smallest and most nimble drone in the field. Our drone's simple and effective design was the only one to successfully complete the payload pickup challenge twice, a feat attributed to extensive testing and iteration. This was my first time piloting in a drone race, and I was proud to outperform many experienced competitors.

My teammate and I at the Virginia Tech Drone Park during the competition

Key Achievements:

• Leveraged Prior Experience: Capitalized on comprehensive knowledge from a previous end-to-end 3D-printed FPV drone project, fast-tracking the research phase and excelling in design execution by incorporating learned principles such as ease of assembly, repairability, and minimal hardware reliance, significantly streamlining the development of this drone design

• Project Leadership: Led the design and production phases, drawing on experience from a prior drone project to streamline development and mentor teammates new to drone technology and 3D printing

Technical Skills Developed:

• Advanced Additive Manufacturing: Prioritized 3D printing to minimize reliance on physical hardware, enhancing the drone's ease of manufacture, assembly, and repair while adhering to competition rules on additive manufactured parts.

• Electromagnetic Payload Integration: Engineered an innovative solution for payload handling by incorporating an electromagnet system into the drone design, enabling effective pick-up and drop-off during the race.

• Custom Control System Development: Implemented a tailored control system with advanced PID and rate profiles in Betaflight, enabling precise maneuverability for landing and payload pick-up via a switch-activated controller setting.

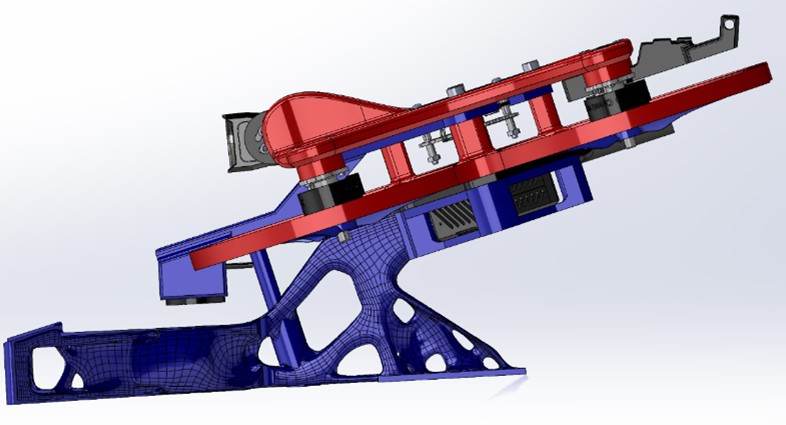

• Advanced Optimization Techniques: Utilized Altair Inspire software’s topology optimization features to enhance our drone design, creating geometries finely balanced for strength and weight while ensuring compatibility with a FDM 3D printing machine

Timelapse of 3D printing a drone component

Project Outcomes:

• Passion for Innovation: Embraced the opportunity to design a new drone from the ground up with enthusiasm, applying lessons from past experiences to significantly refine the model—demonstrating personal growth as an engineer, an eagerness for continuous improvement, and a commitment to leveraging past insights for advanced efficiency and optimization.

• Tight Timeline Execution: Managed a rigorous two-month schedule to conceptualize, design, fabricate, and document the drone build process, resulting in the on-time submission of a detailed design report one month before the competition.

• Leadership and Mentorship: Demonstrated leadership and provided mentorship within the team, guiding group members with little to no experience in drones and 3D printing through the learning curve. By effectively communicating complex concepts and delegating tasks, I showcased crucial engineering skills beyond the technical realm, emphasizing the importance of teamwork and collaboration in achieving project success

Competition Design Report:

For a comprehensive insight into our project, the detailed design report submitted to the ASME EFX drone racing competition is available for review here: View Design Report

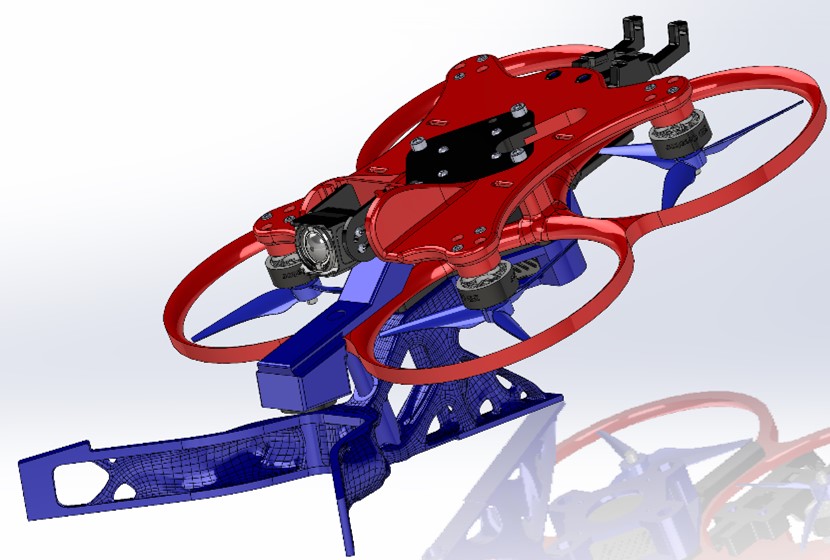

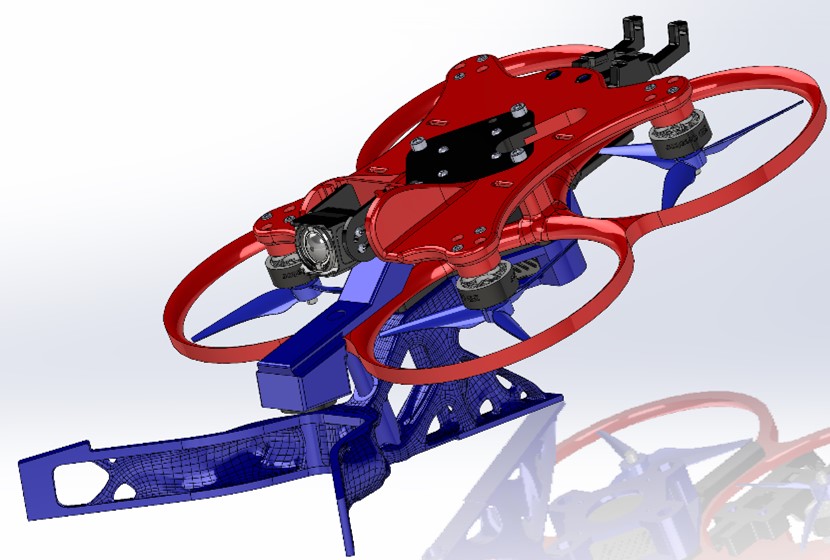

Completed CAD Assembly

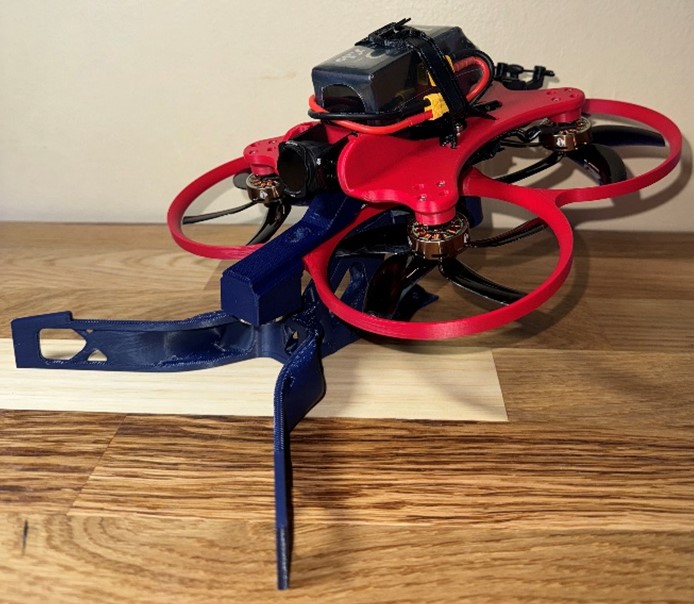

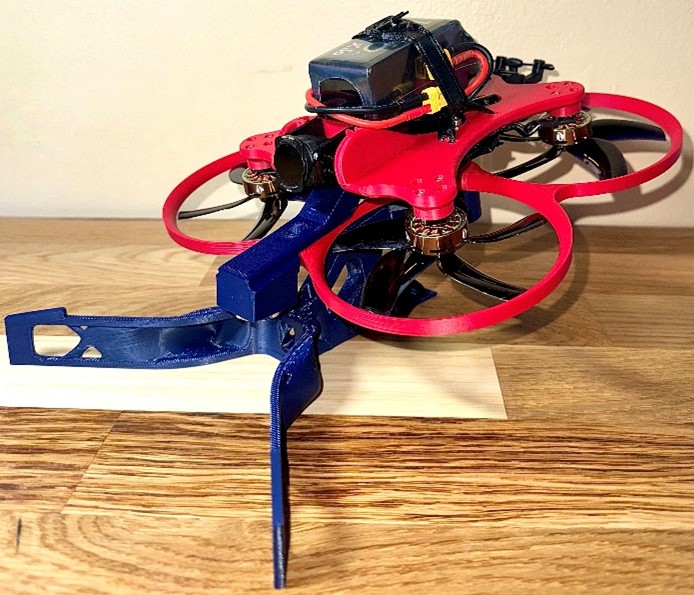

Final Assembled Model

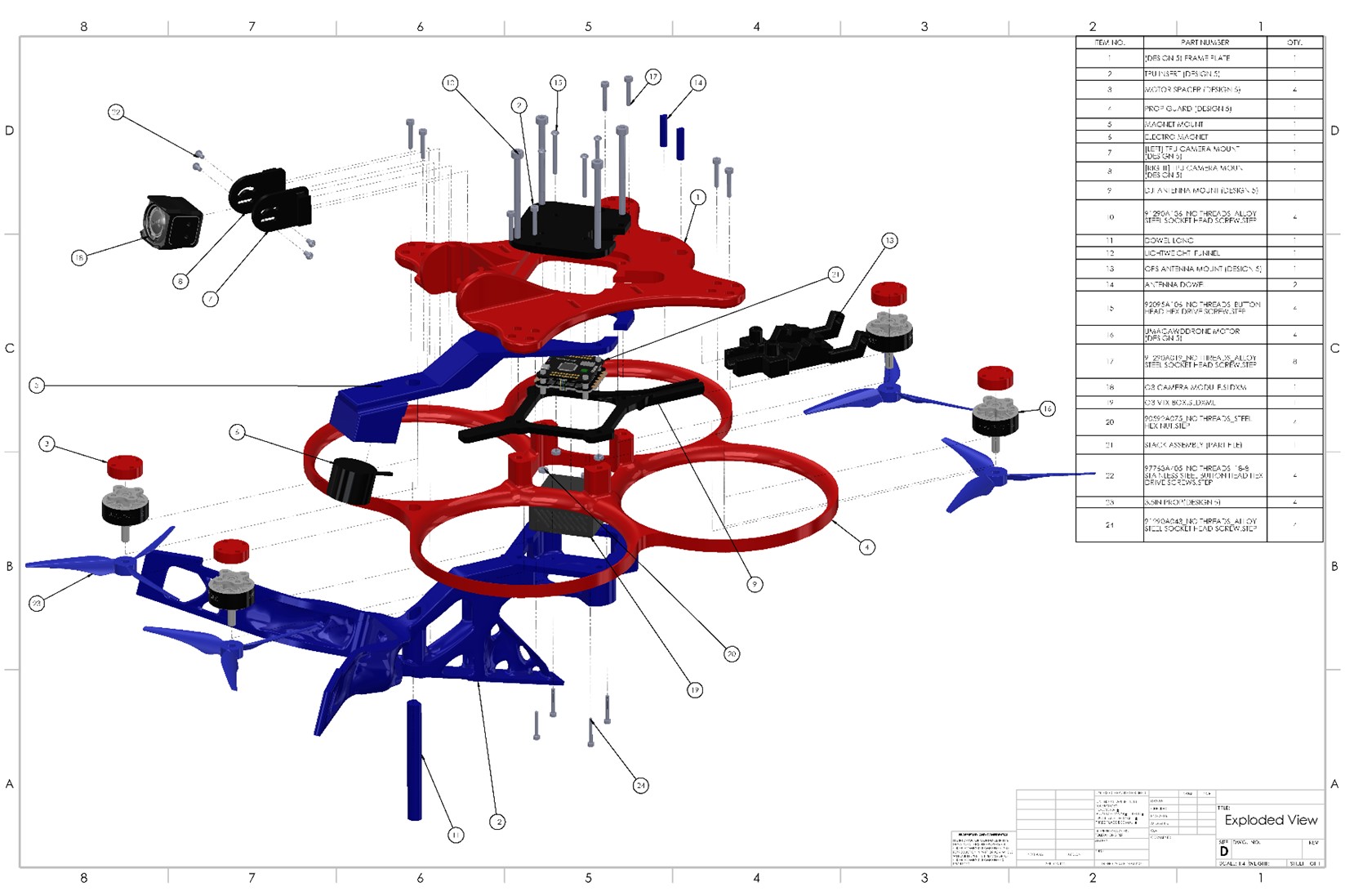

Exploaded View of CAD Assembly

Additional Images of CAD Model and the Final Assembled Drone in its Physical Form